Product portfolio

Nickel 200 (UNS N02200) is commercially pure wrought nickel. It is highly resistant to various reducing chemicals. It can also be used in oxidizing conditions that cause the formation of a passive oxide film, for instance its unexcelled resistance to caustic alkalis. Nickel 200 is limited to service at temperatures below 315℃, because at higher temperatures it suffers from graphitization which results in severely compromised properties. In that circumstance, Nickel 201 is used instead. It has a high Curie temperature and good magnetostrictive properties. Its thermal and electrical conductivities are higher than nickel alloys.

| Nickel 200 Nickel 201 Seamless Alloy Tubes Nickel Pipe | |

| Outside Diameter | 10.3-426mm |

| Wall Thickness | 1.24-40.49mm |

| Length | Up to 25m |

| Standard | ASTM B163, ASTM B167, ASTM B407, ASTM B444, ASTM B622, ASTM B677, ASTM B829,etc. |

| Hastelloy Series | Hastelloy B(UNS N10001), Hastelloy B-2(UNS N10665), Hastelloy B-3(UNS N10675), Hastelloy C-4(UNS N06455), Hastelloy C-22(UNS N06022), Hastelloy C-276(UNS N10276), Hastelloy C-2000(UNS N06200), Hastelloy G-30(UNS N06030), Hastelloy G-35(UNS N06035). |

| Haynes Series | Haynes 230(UNS N06230), Haynes 556(UNS R30556). |

| Inconel Series | Inconel 600(UNS N06600), Inconel 601(UNS N06601), Inconel 617(UNS N06617), Inconel 625(UNS N06625), Inconel 690(UNS N06690), Inconel 718(UNS N07718). |

| Incoloy Series | Incoloy 020(UNS N08020), Incoloy 800(UNS N08800), Incoloy 800H(UNS N08810), Incoloy 800HT(UNS N08811), Incoloy 825(UNS N08825), Incoloy 925(UNS N09925). |

| Monel Series | Monel 400(UNS N04400). |

| Nickel Series | Nickel 200(UNS N02200), Nickel 201(UNS N02201). |

| High Temperature Alloys | GH2132,GH3030,GH3039,GH3128,GH3044,GH4080A. |

| Delivery Condition | Pickled&Annealed, Polished, Bright Annealed. |

| Technique | Seamless |

| Application | National defense, astronautics, transportation, equipment manufacture, shipping, petroleum, nuclear power industry, oil and gas industry, and chemical industry etc. |

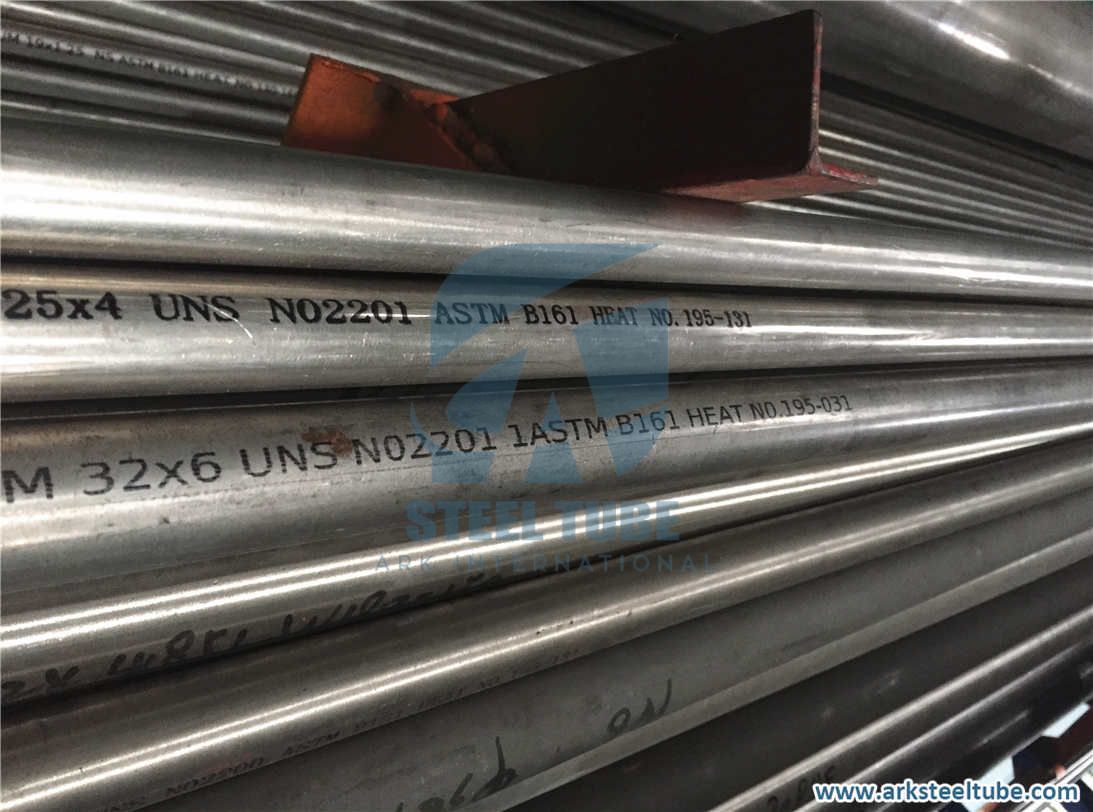

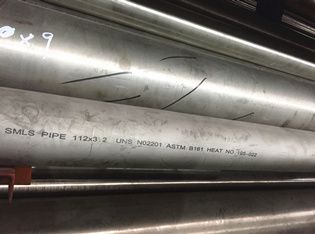

| Marking | LOGO, Standard, Grade, Size, Heat Number. |

| Package | Woven bag, wooden cases, or as per customer's requirement. |

| Quality Requirement | Mill Test Certificate (EN 10204/3.1); Third Part Inspection is acceptable. |