Product portfolio

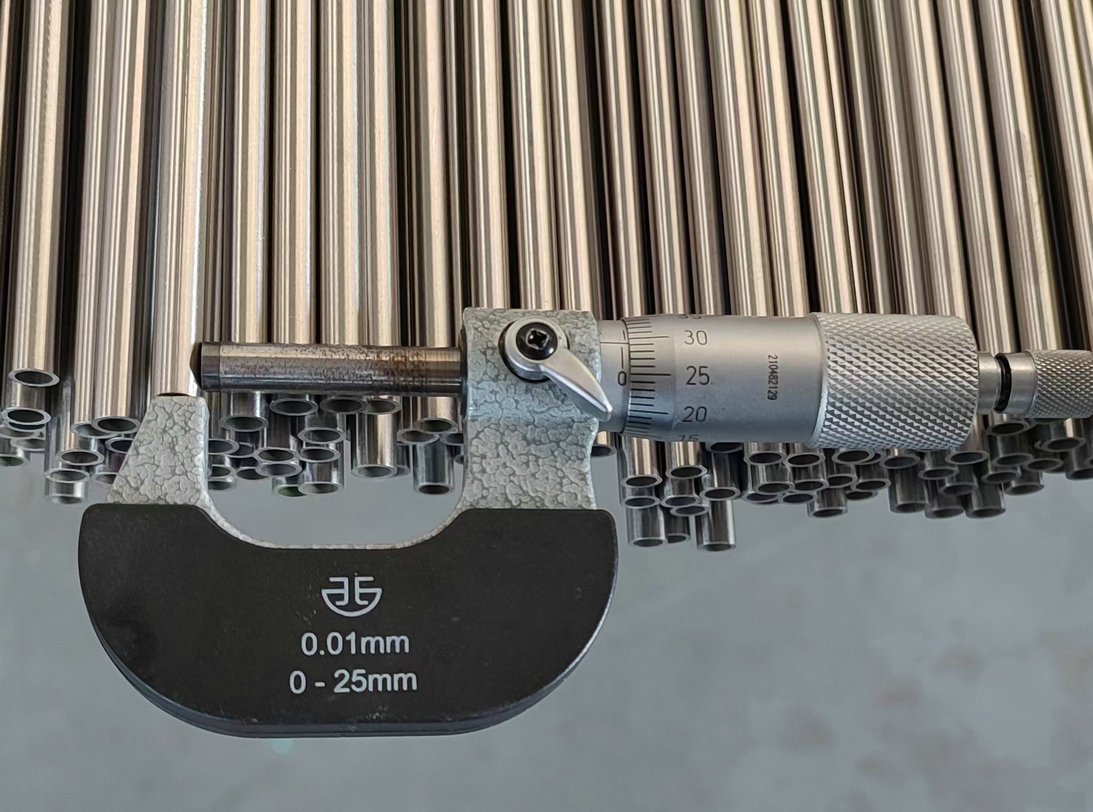

ARK is offering Stainless Steel Capillary Tube Suppliers are in small bore sizes and precise thickness are available as per the requirements of clients. It is widely used in instrumentation Industries. SS 304 capillary tubes and 316 Stainless Steel Capillary Tubing are available in precise cut to lengths are also highly effective in a wide range of temperatures. SS Capillary Tubing are the preferred choice for most applications due to greater corrosion resistance and precision. Stainless steel 316 capillary tubing is generally used for high pressure applications.

| Capillary Tube Stainless Steel for Hydraulic Control Lines and Liquid Gas Transportation Lines | ||||||||||

| Outside Diameter | 0.5-25.4mm | |||||||||

| Wall Thickness | 0.05-5mm | |||||||||

| Length | As customer's requirement; In coil or in straight. | |||||||||

| Standard | ASTM A213/ ASME SA213, ASTM A269/ASME SA269, EN10216-5, etc. | |||||||||

| Grade | TP304, TP304L, TP316, TP316L, TP321, TP247H, etc. | |||||||||

| Delivery Condition | Pickled, Polished, Bright Annealed | |||||||||

| Technique | Seamless/Welded | |||||||||

| Application | Hydraulic control lines, Liquid/ Gas Transportation Lines, Medical devices and equipment’s, Chromatography applications, Measurement devices, Remote thermometer systems Small precision stainless steel antenna, Watches, Car antenna tube, Laser engraving equipment etc. | |||||||||

| Marking | LOGO, Standard, Grade, Size, Heat Number. | |||||||||

| Package | Woven bag, wooden cases, or as per customer's requirement. | |||||||||

| Quality Requirement | Mill Test Certificate (EN 10204/3.1); Third Part Inspection is acceptable. | |||||||||

| Normal Size | |||||

| OD 3/16” | WT0.02” | 4.76x0.51mm | OD3/16” | WT0.028” | 4.76x0.71mm |

| OD3/16” | WT0.035” | 4.76x0.89mm | OD3/16” | WT0.049” | 4.76x1.24mm |

| OD0.24” | WT0.04” | 6x1mm | OD0.24” | WT0.06” | 6x1.5mm |

| OD1/4” | WT0.02” | 6.35x0.51mm | OD1/4” | WT0.028” | 6.35x0.71mm |

| OD1/4” | WT0.035” | 6.35x0.89mm | OD1/4” | WT0.049” | 6.35x1.24mm |

| OD1/4” | WT0.065” | 6.35x1.65mm | OD5/16” | WT0.028” | 7.94x0.71mm |

| OD5/16” | WT0.035” | 7.94x0.89mm | OD5/16” | WT0.049” | 7.94x1.24mm |

| OD5/16” | WT0.065” | 7.94x1.65mm | OD3/8” | WT0.028” | 9.53x0.71mm |

| OD3/8” | WT0.035” | 9.53x0.89mm | OD3/8” | WT0.049” | 9.53x1.24mm |

| OD3/8” | WT0.065” | 9.53x1.65mm | OD0.4” | WT0.04” | 10x1mm |

| OD0.4” | WT0.06” | 10x1.5mm | OD0.4” | WT0.079” | 10x2mm |

| OD0.47” | WT0.065” | 12x1mm | OD0.47” | WT0.06” | 12x1.5mm |

| OD1/2” | WT0.028” | 12.7x0.71mm | OD1/2” | WT0.035” | 12.7x0.89mm |

| OD1/2” | WT0.049” | 12.7x1.24mm | OD1/2” | WT0.065” | 12.7x1.65mm |

| OD0.55” | WT0.04” | 14x1mm | OD0.55” | WT0.06” | 14x1.5mm |

| OD5/8” | WT0.028” | 15.88x0.71mm | OD5/8” | WT0.035” | 15.88x0.89mm |

| OD5/8” | WT0.049” | 15.88x1.24mm | OD5/8” | WT0.065” | 15.88x1.65mm |

| OD5/8” | WT0.083” | 15.88x2.11mm | OD0.63” | WT0.065” | 16x1mm |

| OD0.63” | WT0.06” | 16x1.5mm | OD0.63” | WT0.079” | 16x2mm |

| OD3/4” | WT0.04” | 19.05x1mm | OD3/4” | WT0.049” | 19.05x1.24mm |

| OD3/4” | WT0.065” | 19.05x1.65mm | OD3/4” | WT0.083” | 19.05x2.11mm |

| OD1” | WT0.049” | 25.4x1.24mm | OD1” | WT0.0665” | 25.4x1.65mm |

| OD1” | WT0.083” | 25.4x2.11mm | OD1” | WT0.1” | 25.4x2.54mm |

Application:

Instrument Tubing

Chromatography Tubing

Hydraulic Tubing

High Pressure Tubing

Cleaned Tubing

Heat Exchanger

Etc.

Inspection:

PMI Test

Hydraulic Test

Eddy Current Test

Non-Destructive Test

Etc.